In systems where the power sources include batteries, UPS, and emergency generators, a system is needed that can control and manage all these power sources and optimize energy consumption. In the GCM system, which includes a control board, data on the main power supply, batteries, and generators are collected. Based on this information and the defined and configured control algorithm, commands for turning the generator on and off are issued in three ways:

|

Basic Features

- Operation in both automatic and manual modes

Measurement of essential generator parameters (output voltage, oil pressure sensor, alternator output, temperature sensor)

Measurement of essential battery parameters during charging (voltage and charging current)

Measurement of battery charging current via shunt on the negative battery terminal or Hall effect sensor in the charging current path

Measurement of main power supply voltage in either three-phase or single-phase

Measurement of main power supply frequency in single-phase

Measurement of AC current of the main power supply and generator output using Hall effect sensor or CT current transformer

Control of gasoline and diesel generators (configurable generator type and cutoff mode by the user in the hardware program)

Two adjustable methods for generator shutdown: short-circuiting the spark plug in gasoline engines and closing the fuel valve in diesel engines

Heater output for diesel generators before issuing the start command

-Protection of voltage inputs against over-voltage

Measurement of generator fuel tank level in discrete three levels

Adjustable start command time for the generator from zero to 10 seconds

Adjustment of voltage and current threshold values for battery and generator for optimal system performance under various conditions

Adjustment of sensor measurement coefficients for precise measurement and calibration of sensor outputs

User interface including a graphical display and 4 control buttons

Windows-based monitoring and control software

Error reporting capability on the display and software

Recording of generator runtime and display of total generator runtime since the installation of the GCM control system

Communication Capabilities

- Ability to interface with software via LAN and serial communication

- Capability to receive start and stop commands for the generator via DTMF signals over the telephone line

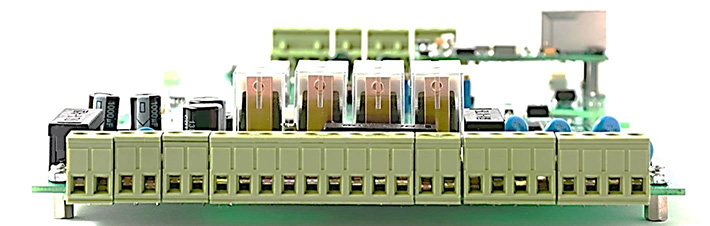

- Optional LAN and DTMF converter modules can be installed on the control board if needed

- Ability to configure IP and other network module parameters via software

- Provision for a password to send settings to any hardware